THE PROCESS

Biogas is produced from organic waste (carbon) which biodegrades by means of bacteria in an anaerobic environment. This process is expedited at a process temperature of 38°C/100°F (mesophilic) or 52°C/125.6°F (thermophilic) in the plant’s digester.

The biogas plant receives all kinds of organic waste – typically livestock manure and organic industrial waste. The dry solid in livestock manure contains carbon, among other things, and in the process this carbon is transformed into biogas, a compound of methane (CH4) and carbon dioxide (CO2).

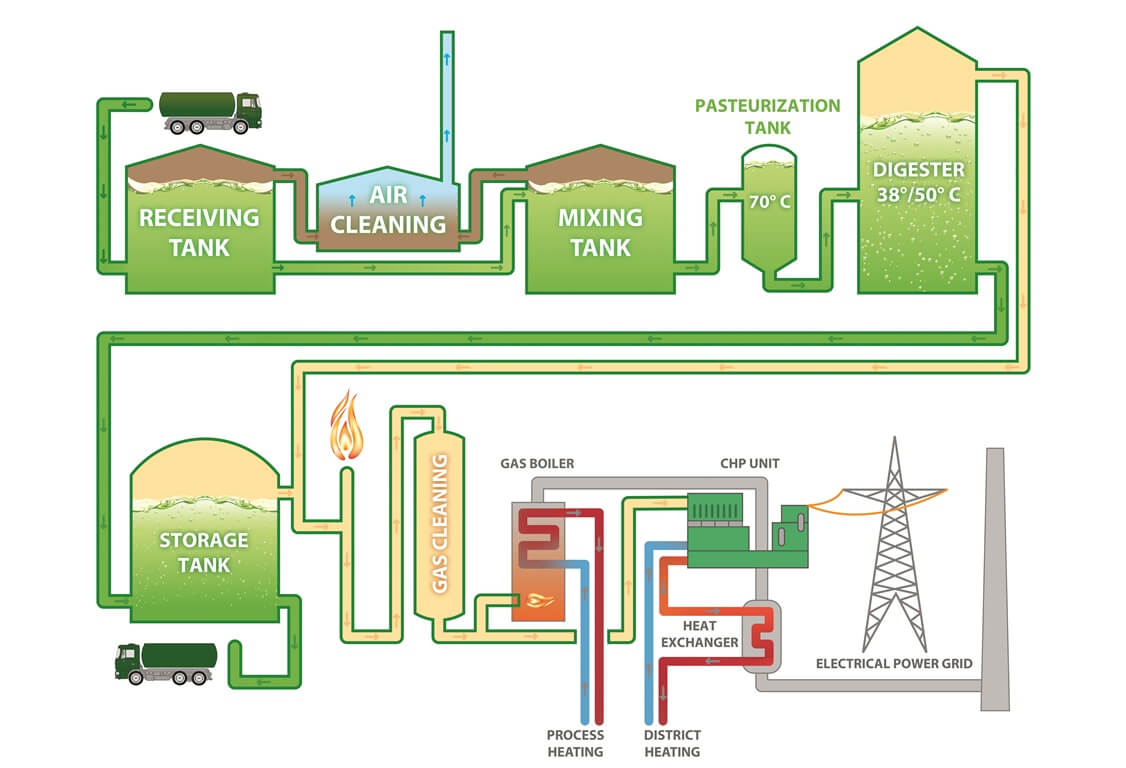

The manure and waste are mixed in the plant’s receiving tank before being heated to 38-52°C/100-125.6°F and pumped into the digester in which the biogas is produced. The biomass stays in the digester for 2-3 weeks and the fermented slurry can subsequently be used as crop fertilizer. This fertilizer has improved qualities such as less odour inconveniences when spreading the slurry and significant reduction of green house gasses.

GREEN ENERGY

Typically, the biogas is utilized to produce electricity and district heat in the plant’s gas engine (CHP unit). The electricity is sent into the power grid and the heat is used by local consumers.

Furthermore, biogas can be upgraded to natural gas and injected into the natural gas grid or be used as fuel for transportation.

Below is a chart illustrating the processes of an Avenam Biogas plant. Not all the parts are compulsory but the chart shows a complete plant including all the significant components.